About Unnos Systems

Engineered precision. Built in Wales

Unnos is a Welsh modular building company creating architecture-grade modules from homegrown timber. We combine digital design, factory control and the craftsmanship behind Kenton Jones to deliver fast, precise and low-impact buildings for professional clients.

Our name nods to the Welsh folk idea of raising a home in a single night. Since 2008, we’ve translated that spirit of speed and ingenuity into practice: an engineered timber system that lets us design, manufacture and deliver modules rapidly—without compromising detail or finish. Today, Unnos Systems builds volumetric and panelised solutions with the same obsession for quality that defines our workshop.

Where we come from

Roots in Kenton Jones craft

Unnos grew from the heritage of Kenton Jones, a family workshop hand-crafting kitchens and joinery since the 1970s. Two generations of design and making taught us timber selection, joinery tolerances and finish quality the standards we carry into modular construction. That lineage includes sourcing local wood, building teams around mastery and delivering for discerning clients principles that still guide our factory today.

Our Journey

Roots in Kenton Jones craft

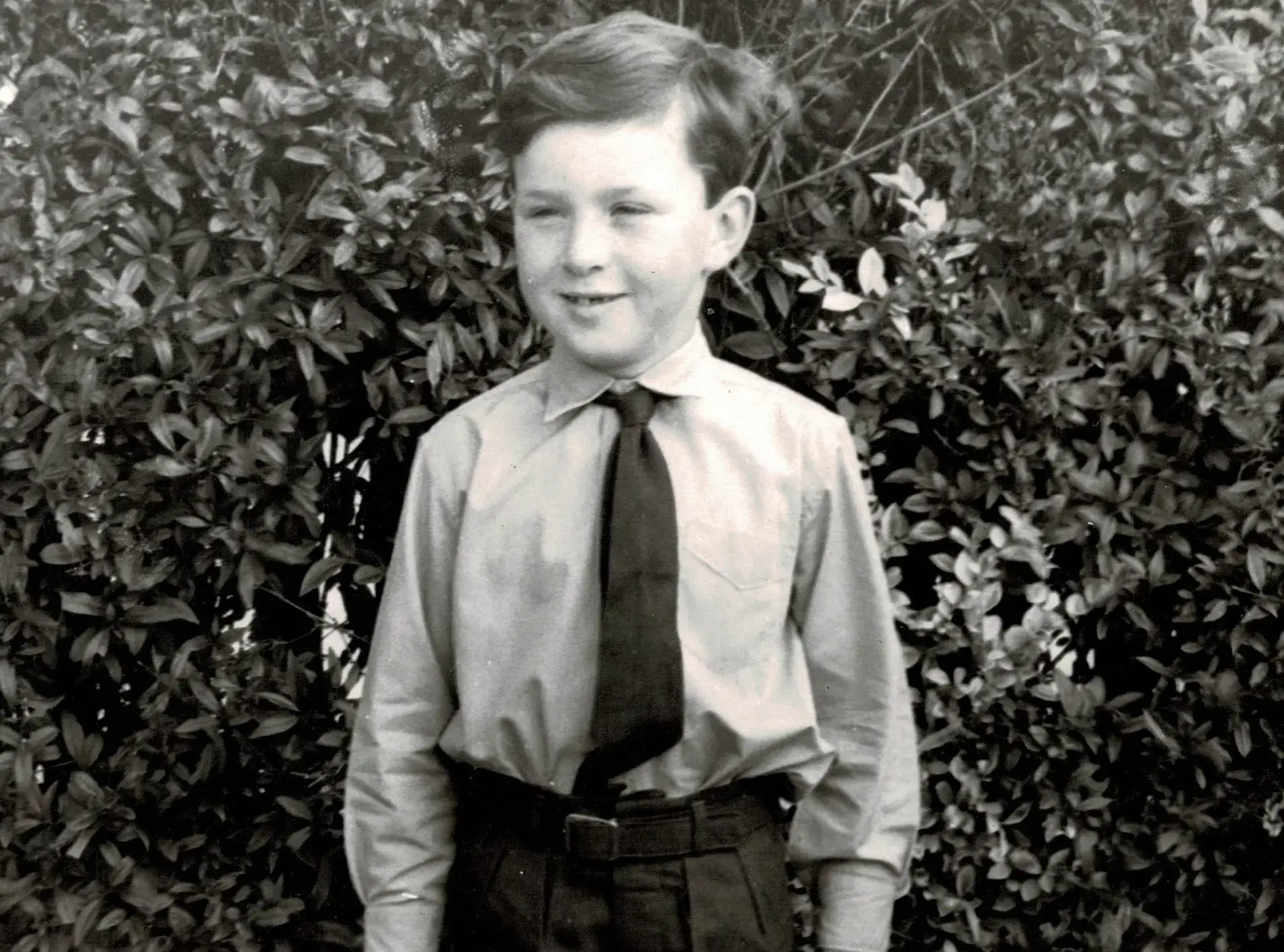

Early 1960s

Starting at a young age

At the age of six, Kenton was gifted his first set of woodworking tools. As his passion for the subject grew, he always went against the grain in search of new and more refined techniques.

Late 1960s

A growing passion

As a young teenager, he would spend hours in his self-made joinery shop above a cow shed on the family farm and bought his first piece of milling equipment with his brother, Michael.

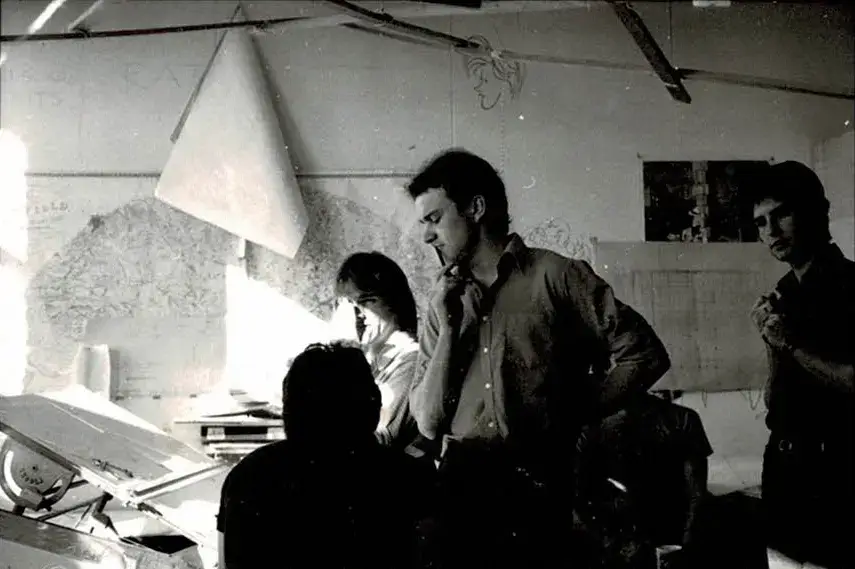

1973

Studying architecture

Aged 19, Kenton attended Nottingham University to study architecture. This degree later proved useful for removing a piece of non-structural oak from the family home. The building still bears the scars today.

1977

The first step towards kitchens

After returning home, Kenton started a design-build company and his former primary school teacher, knowing his love of timber, asked him to make a kitchen out of reclaimed school desks.

1980

The very first Kenton Jones kitchen

Kenton and Michael acquired their first local Oak tree specifically for producing quarter-sawn boards to make the first Kenton Jones kitchen. The only way to mill such big pieces was with a large chainsaw.

1981

A growing business

Needing his own space, Kenton decided to move his workshop to the old Mill at Leighton farm where he could only afford to rent the fifth floor. He also agreed to treat the building for dry rot as part of the deal.

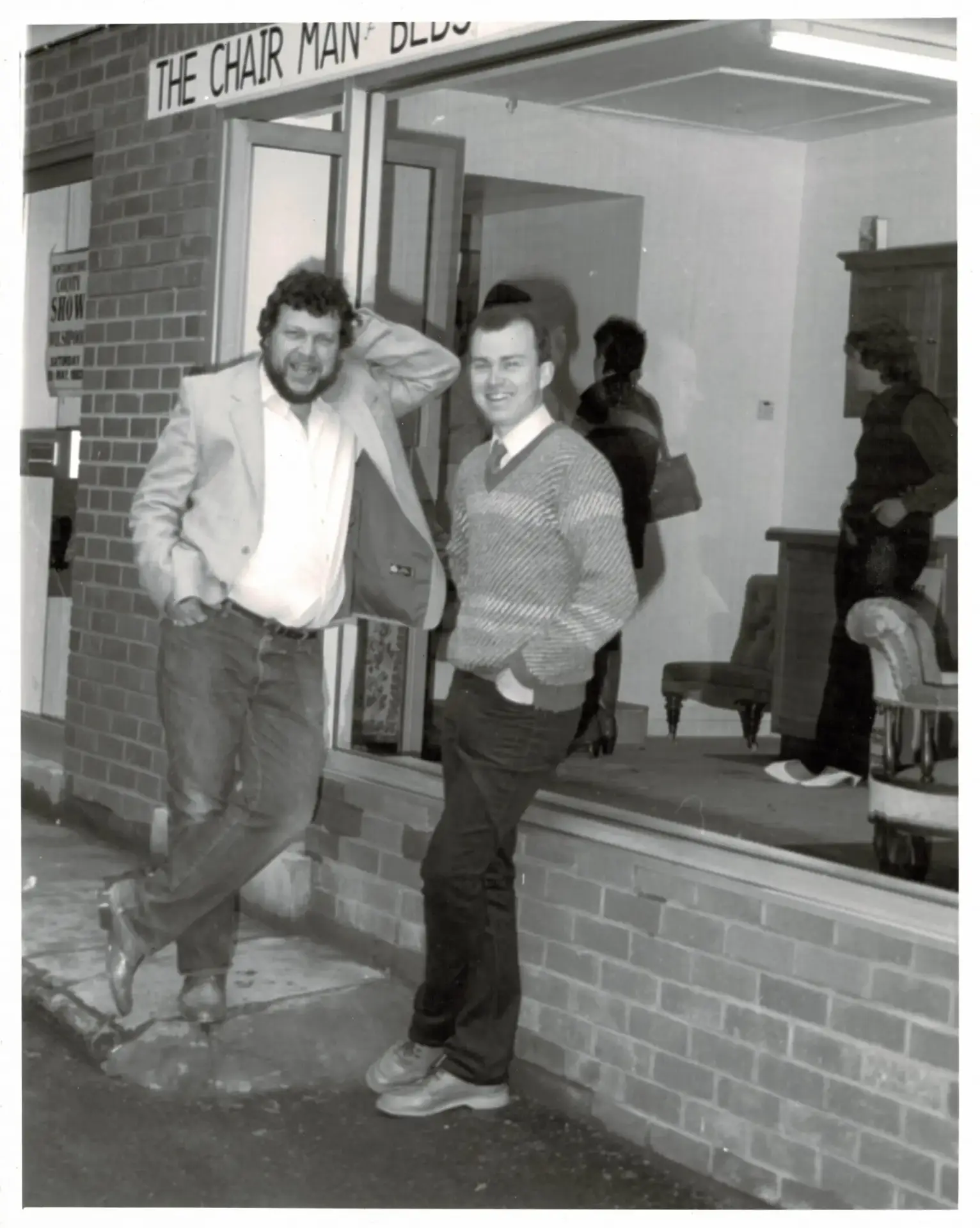

1983

Kenton Jones kitchens Welshpool showroom

After meeting upholsterer Chris Compton, they opened a showroom together in Welshpool during Easter where Kenton was able to showcase his craftsmanship and start growing the business.

Mid 1980s

The sawmill

Michael went on to set up his own sawmill, purchasing a horizontal bandsaw for processing large locally sourced trees for Kenton.

Late1980s

Transport for the mill

Michael then purchased an ex-army lorry for transporting the large logs to the mill.

1990s

A fast-growing business

As he gained more clients, Kenton was also inspired to start producing solid wood flooring from locally sourced timber. He soon took on all floors of the mill and several other buildings at Leighton farm.

1997

New premises opened by Lembit Opik

Acquiring his own premises on Henfaes Lane in Welshpool, Kenton gathered a team of men dedicated to honing their craft and, drawing on his architectural background, they were committed to realising client visions.

2001

A kitchen fit for royalty

Kenton was honoured with the opportunity to design, build and install a kitchen at Highgrove House for the then Prince of Wales, made from locally sourced Welsh Oak trees.

2008

R&D engineered timber system

As the company grew we began engineering a system around Welsh and homegrown timber: structural frames, repeatable connections and components designed for speed without sacrificing precision. The aim was simple pair natural materials with a reliable, modern process.

2018–2023

From components to complete modules

Partner projects moved us from parts to architecture-grade modules: digital design → factory manufacture → watertight shells → controlled interiors. Keeping builds dry throughout assembly meant consistent tolerances, cleaner installs and fewer site-time variables.

Today

Architecture-grade modular delivery, B2B

Unnos Systems now serves architects, developers, main contractors and public-estate teams, delivering high-finish, homegrown-timber modules from Wales to sites across the UK. The ethos from the workshop remains: precision, natural materials and builds that respect their setting.

Our History

Passing down the art.

Honing his craft from a young age, Kenton was born with an innate passion for woodwork. Combined with an architectural background, he has always strived to give every client something truly unique to them.

Kenton has since passed down his skills and knowledge to his son, who is now in turn training the next generation. From Welshpool to Shropshire and beyond, our creations embody the artistry and values that run through our family as we continue to uphold the local legacy of quality craftsmanship that permeates every project undertaken.

WHO WE ARE

Our Expert Teams

Design Team

Installation Team